Week 1: Wood

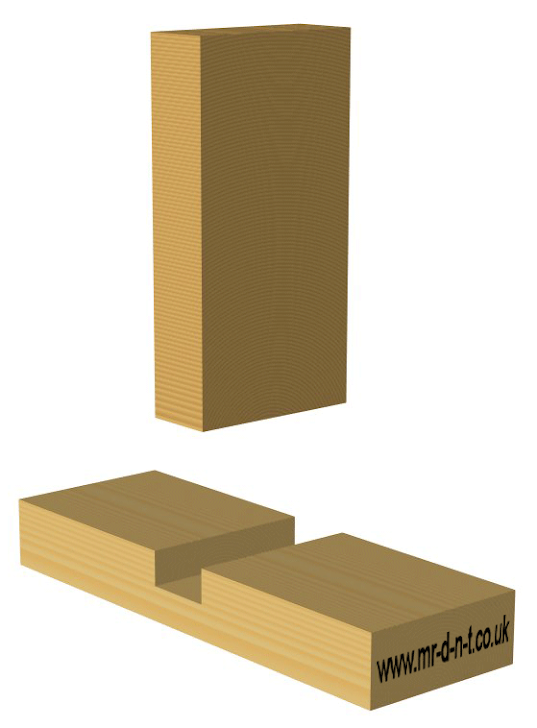

Topic: Making a Housing Joint

Sub-topic: Wood

Modality: Face-to-face

Level: Form 5

Duration: 3 hrs

No. of students: 25

Aim of the lesson:

The aim of this topic is to provide students information on one of the oldest raw material known that is wood.

Learning Objectives:

At the end of the lesson, students should be able to:

· Identify wood

· Distinguish between wood and timber

· List the uses, properties and colour of softwoods and hardwoods

· Identify how wood is processed

· Appreciate the great variety of hardwoods and softwoods commonly used in society.

· Answer questions regarding the properties, uses and common forms of woods.

Assessment criteria:

Ø Activity 1 carries 10 marks

Ø Activity 2 carries 10 marks

Ø Activity 3 (Hot potatoes-JMatch) carries 5 marks

Ø Activity 4 (Hot potatoes- multiple choice) carries 5 marks

Total marks: 30

Presenting the Lesson

· Introduction

· What is wood?

· Difference between wood and timber

· Where wood comes from?

· Tree and wood identification

classification of timbers (s/w and h/w)

classification of timbers (s/w and h/w)

· How wood is processed?

· Wood’s strength

· Everyday uses of wood in your home

· Activities

Introduction

We are surrounded by trees and yet we actually pay very little attention to them on a day to day basis. In fact, many people could not identify some of the most common species that are living right in their back yards. Another mystery to most is the difference between Wood and Timber and Hardwood and Softwood.

What is wood?

Wood is one of the oldest raw materials known, yet it continues to play a major role in modern-day life. It is used in the construction of furniture, housing, toys and paper making. Wood that is used for furniture and carpentry works are obtained from trees. However, not all trees provide timber for woodworking.

Difference between wood and timber

Wood is used to refer to materials in its natural state; however timber refers to it after it has been modified by men. Wood can be used to produce a fire. On the other hand timber can be used to make a house.

Advantages of Timber

Timber is one of the most environmentally friendly materials available. It is renewable, biodegradable, non-toxic, energy efficient and greenhouse gas friendly. All other major construction materials are finite. One day they may run out. Trees can be cut down and replanted. Timber can be recycled and when it reaches the end of its life it can be disposed of with minimal impact to the environment because of its non-toxic nature.

Timber is one of the best insulation materials. It is 5 times better as an insulator than concrete, 400 times better than steel and 1,770 times better than aluminium. That makes it an excellent material for use in construction to reduce energy bills for both households and business.

Timber is extremely versatile, beautiful and is one of the oldest and most natural construction materials known to man. Weight for weight, wood has probably the best engineering properties of any material. Many of its structural properties result from the microscopic layout of its cells and cell walls. Wood is an extremely versatile structural material, ingeniously arranged to provide a living structure that combines both strength and flexibility.

Where wood comes from?

One of the best things about wood and wood products is that they are made from renewable natural resources.

When something is renewable, it means that it can be replaced, or brought back. Trees are renewable because they grow back after they've been cut down. So if you manage your forests in the right way, you can grow back the trees you cut down forever.

When something is natural, it means that it comes from nature. Trees come from nature.

When something is a resource, it means that it is valuable to humans for making other things. Trees and wood are resources because there are lots of valuable things we can make from wood.

So, when you put the whole phrase together, a renewable natural resource is something that comes from nature that's valuable to people, and can be continually restored.

Tree and wood identification

Ø Classification of timbers

Timber is a natural product of solid wood from a tree which has been sawn to sizes suitable for building and construction purposes (structures for buildings, beams, columns etc). Timbers are also used for making a variety of furniture in homes and offices and tool bodies, such as for wooden planes and handles for chisels and saws.

There are two different types of timber:

a. Softwood

b. Hardwood

SOFTWOOD

What are Softwoods?

The term softwood is used to describe wood from conifers. The conifers that are botanically known as gymnosperms are distinguished by their tall slender trunks, narrow or needle-like leaves like those of the Christmas tree, and naked seeds in cones. They are called evergreen trees because their leaves mostly remain green throughout the year without shedding.

They grow mainly in cold climates such as northern Europe and Great Britain but are not common in tropical countries where the climate is warm. Commercially, timbers produced from these trees are called softwoods though, physically, some are harder than the hardwoods.

Softwoods are fast-growing, can be easily cultivated, and produce relatively straight trunks, which makes harvesting and processing much less expensive. Conifers are also used in the manufacture of fibreboard and paper.

Softwood is the source of about 80% of the world’s production of timber.

Which trees produce softwood?

Softwood is produced by pine, spruce, cedar, fir, larch, hemlock, cypress, redwood and yew trees.

Softwoods chooser chart

The table below displays a variety of common softwoods. It explains the uses of each and provides information on the advantages and disadvantages of using each one.

Softwoods Chooser Chart | ||||

Name | Uses | Advantages | Disadvantages | Colour |

Redwood Scots pine, pine, fir. | Suitable for all types of inside work. Used for wood turning. Can be used outside with suitable preservatives. | Fairly cheap and readily available. Easy to work and finishes well. Durable. | Knotty. | Cream to pale reddish brown. |

Parana Pine | Staircases and furniture. | The best quality internal softwood. attractive grain. Available in long and wide boards. Works easily. | Lacks toughness. Does tend to warp and can be expensive. | Pale yellow with attractive streaks. |

Western Red Cedar | Cladding for the outside of buildings. | Resistant to insect attack because of natural preservative oils. Weather and dry rot. Knot free. Very durable. Very easy to work. | More expensive than red or whitewood. Not that strong. | Dark reddish brown. |

Douglas Fir | Outside construction. Ladders and masts. | Water resistant. Knot free. durable and easy to work. | Splits easily. | Attractive reddish brown. |

Whitewood Spruce | General outside work. | Resistant to splitting. Easy to work. | Small hard knots. Not durable. | Plain creamy white. |

When to use Softwood?

No matter which types of softwoods you choose to use in your projects, keep in mind that most softwoods are developed for construction uses, and not necessarily for building furniture. Keep in mind that softwoods need to become acclimated to the environment in which the finished project will reside before beginning wood working to avoid excessive moment after the project is completed. Softwoods can be a fine choice when building utilitarian projects (cabinets for the woodshop, painted projects, dog houses, etc.), but should probably be avoided when you intend to use stain for the finished or want to use the completed piece to be employed inside the house. In general, softwood is easy to work with; it therefore forms the bulk of wood used by man. Softwood has a huge range of applications: it is the primary material used for building components, and is also found in furniture and other products such as millwork. (moldings doors, windows). Softwood is also used in the production of paper, and for various types of boards such as MDF (Medium Density Fiberboard).

HARDWOOD

What are Hardwoods?

The Deciduous trees can be as tall as the conifers but they have a bigger diameter. The botanical name for this class of trees is the angiosperms. They have broad leaves that dry up and fall during the dry season in tropical areas such as African countries. Some of them, however, do retain their green leaves throughout the year. Deciduous trees bear a great variety of flowers and fruits containing seeds, often called dicotiledon seeds. Timbers produced from this class of trees are known commercially as Hardwoods. Some of them, such as Balsa are actually softer than some softwoods. Other examples of Hardwoods are Mahogany, oak, teak, and beech.

Many Hardwoods are softer and lighter than some softwoods. Hardwoods are employed in a large range of applications, for example (but not limited to), construction, furniture, flooring and utensils. Hardwood species are more varied than softwood. There are about a hundred times as many hardwood species as softwoods. Hardwood are far more resistant to decay than softwoods when used for exterior works.

Some examples of hardwoods include ash, beech, birch, black cherry, black walnut, American chestnut, elm, hickoly, holly, locust, magnolia, maple, oak, poplar, red alder, redbud, sassafras, sweetgum and sycamore.

Hardwood Chooser Chart

Hardwoods Chooser Chart | ||||

Name | Uses | Advantages | Disadvantages | Colour |

Beech | A very Hard wood used for furniture, floors, veneers and wooden toys. | Hard, tough and very strong. The close grain withstands wear and shocks. | Not suitable for outside work because it is not durable to moisture changes. It is difficult to work an does warp. | White or pinkish. |

European Oak | Boat building, garden furniture, quality furniture and gate posts. | Very strong and durable. It is both hard and strong. Easier to use than beech. | It is heavy and expensive. It is prone to splitting and because of it's tannic acid content it can corrode iron and steel fittings. | Light to dark brown. |

Elm | Turnery, garden furniture when correctly treated. some furniture. | Elastic, tough, durable, does not split easily, medium weight, good for use under water. | It will warp unless well seasoned. | Light reddish brown. |

Teak | Ships decks, garden furniture, veneers. | It is naturally durable to moisture because of it's oil content. It does not corrode iron and steel fittings. it is hard and strong. | It is difficult to glue because of the oil content. It blunts tools very quickly. | golden brown. |

African Mahogany | Shop fittings, furniture, veneers. | Available in wide and long boards. easy to work, fairly strong. | Warps, Hardness varies. | Pink to reddish brown. |

Meranti | It is a mahogany substitute. furniture, interior joinery. Can be used outside if correctly preserved. | It is cheaper than mahogany. | Does not polish as well as mahogany. | Dark red or yellow. |

African Walnut | High class furniture. Sometimes used as teak substitute in furniture. | Attractive appearance. Available in larger sizes. | It can be difficult to plane and finish. | Bronze yellowish-brown with irregular dark lines. |

Afrormosia | Sills, gates, doors, stairs, floors. | Works well, durable. | Stains in contact with iron and moisture. | Yellow to dark brown. |

Activity 1:

1. Which type of hardwood would be suitable to make tough kitchen surface tops from? The surface would have to withstand shocks and wear.

2. If mahogany proves too expensive to use what would be an ideal substitute?

3. Give two examples of suitable hardwoods that may be used to make quality garden furniture?

4. A manufacturer of intends to create wooden sailing boats. Suggest a suitable hardwood?

5. Explain why European oak is not normally joined together with iron and steel fittings?

6. Name one property of Teak which makes it difficult but not impossible to use?

7. Why is Western Red Cedar a suitable material to use in the construction of children's playgrounds?

8. Name a softwood that is water resistant?

9. Explain what happens to Afrormosia if is placed in contact with iron in damp conditions?

10. Name a hardwood which is both elastic and strong. This type of hardwood is also durable and does not split easily?

2. If mahogany proves too expensive to use what would be an ideal substitute?

3. Give two examples of suitable hardwoods that may be used to make quality garden furniture?

4. A manufacturer of intends to create wooden sailing boats. Suggest a suitable hardwood?

5. Explain why European oak is not normally joined together with iron and steel fittings?

6. Name one property of Teak which makes it difficult but not impossible to use?

7. Why is Western Red Cedar a suitable material to use in the construction of children's playgrounds?

8. Name a softwood that is water resistant?

9. Explain what happens to Afrormosia if is placed in contact with iron in damp conditions?

10. Name a hardwood which is both elastic and strong. This type of hardwood is also durable and does not split easily?

How wood is processed?

Lots of times, wood will be cut into boards and used as it is for hardwood floors, tables, chairs, etc.

But, lots of times, people will modify or change the wood before it is used. Think of the paper in all of your books, that's wood, but it is definitely been modified. As examples, check out the book, construction paper, and toilet paper in the picture above, that's all wood!

When wood is modified before it is used, we say that it is processed. Things made from processed wood are called wood products.

Some of the most important wood products we use everyday are boards, plywood, paper, and particleboard.

Explanations are given below about how all of these wood products are made, and how they are used.

Boards

Boards are made by cutting logs from tree trunks into long, thin, and flat pieces that are often called lumber.

Boards are used to make hundreds of things from the walls, floors, ceilings, and roofs in our houses, to the furniture and cabinets we use every day and baseball bats, golf clubs, pianos, clarinets, guitars, hammer handles, jewelry boxes, pencils, and lots of other things.

Hardwood Sawmill Field Trip

Converting logs into boards is a pretty simple process that involves cutting boards from logs, squaring up the edges, and cutting the boards to the right length. This is done by hand in some parts of the world, but most of the lumber is produced in modern sawmills with lots of machinery.

Wood’s strength

We have all heard people remark how strong wood is. That is a very true statement. Wood is very strong. What exactly do we mean by strength? Strength can be measured in so many different ways.

|

Examples of strong wood

Baseball bats are made from hickory. Hickory is a very hard wood and won't change shape or splinter when it receives a hard impact (like from a baseball). |

Floors and stairs are often made from oak. Oak is a very dense wood and can endure the everyday walking and moving of people. A less dense wood would be worn away more quickly.

Power lines poles are usually made from pine trees. This is because they are strong enough to support the heavy lines. In addition, they have to be somewhat flexible, so when the wind blows the poles and they won't break.

Everyday uses of wood in your home

We did see lots of wood everywhere in the house.

Outside we found:

- plywood sheathing under the roof

- plywood under the siding

- shingle siding made from wood

- and the wood deck

In the Living room we found:

- wood flooring

- wood under the floor

- a wood picture frame

- a wood window frame

- wood floor and door molding

- a newspaper and magazines made from paper which comes from wood

In the Kitchen we found:

In the Dining room we found:

In the Bedroom we found:

In the Bathroom we found:

Wood is everywhere! |

Activity 2

Quiz scavenger hunt

Quiz scavenger hunt

Print out this list and try to find all of these items around your house. You will be surprised just how much wood you use every day.

- Photo film

- Rayon clothing

- Firewood

- Wooden furniture

- Apples, oranges or other fruits from trees

- Cardboard box

- Newspaper

- Ice cream

- Vanilla extract

- Shampoo

- Toilet paper

- Salad dressing

- Wood doors and frames

- Picture frames

- Books and paper

- Cereal box

- Hardwood floors

- Wooden musical instruments

- Pencil

- Tools with wood handles

- Charcoal

- Toothpaste

Activity 3: Matching (Hot potatoes)

Activity 4: Multiple choice (Hot potatoes)

If you had financial problems, then it is time for you to smile. You only need to contact Mr. Benjamin with the amount you wish to borrow and the payment period that suits you and you will have your loan within three working days. I just benefited for the sixth time a loan of 700 thousand dollars for a period of 180 months with the possibility of paying before the expiration date. Mr Benjamin has be helping me with loan.Make contact with him and you will see that he is a very honest man with a good heart.His email is lfdsloans@lemeridianfds.com and his WhatApp phone number is + 1-989-394-3740

ReplyDelete