Week 3: SAFETY RULES IN THE SCHOOL WORKSHOP

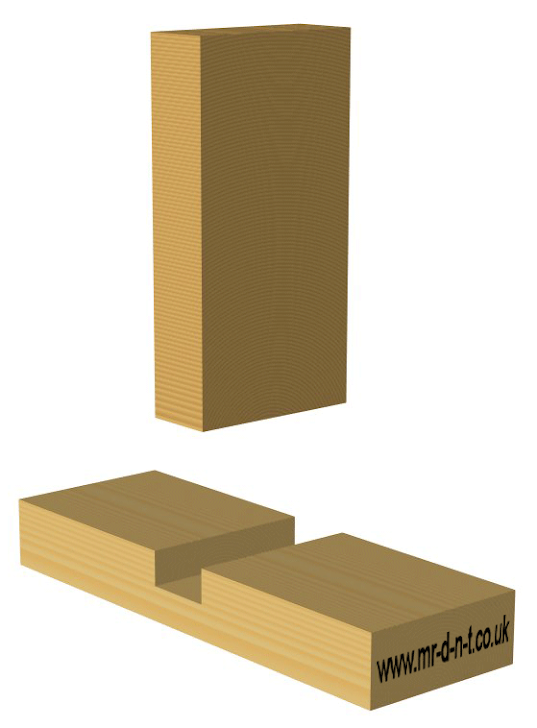

Topic: Making a Housing Joint

Sub-topic: Safety rules in the school workshop

Modality: Online

Level: Form 5

Duration:

No. of students: 25

Aim of the lesson:

The aim of this topic is to help students gain knowledge and understanding about workshop safety and safe working practices in a practical environment.

Learning Objectives:

At the end of the lesson, students should be able to:

Identify potential safety hazards in the workshop.

Outline the basic workshop safety requirements.

Ensure that safety standards and practices are implemented and maintained in the workshop.

Ensure that appropriate information, instruction and training are given to them to perform work safely.

Ensure that the facilities and equipment provided for them are safe and suitable for the types of work to be carried out.

Assessment criteria:

Students will be assess on the work posted on my Blog: Ricardo.dinstudio.com

Marks about each exercise has been clearly mentioned to them.

Total marks: 30

Presenting the Lesson

· Intro

· General rules regarding safety

· Clothing and Footwear

· Movement in the workshop

· The Workshop floor

· Fire and Accidents (Safety signs and symbols)

· Using tools and machines

· Activities:

Introduction

Activity 8:

Make a list of the things you think may cause accidents in a workshop.

Clearly write your name on your worksheet and send it on my Email-address for correction: ricardolentete@yahoo.com

General rules regarding safety

The tidiness and cleanliness of a workshop not only reflects the character of the person using it, but also helps in the prevention of accidents. Safety depends on the attitude of mind rather than a set of rules.

Workshop and personal cleanliness are essential, e.g. oil or bits of metals left on the floor are always a source of danger.

Barrier creams should be used before starting any dirty work and hands should be washed on completion. Minor cuts and scratches should be treated to prevent infections.

It is reported that many accidents are caused by carelessness, and failure to observe safe work practices.

Some of the safety rules which should be properly observed are listed below.

1. Use proper safety devices and facilities when provided.

2. Do not indulge in joking and fooling.

3. Learn to recognise dangerous hazards and to report them promptly.

4. Always keep work area clean and tidy.

5. Wear safety glasses and proper protective clothing when required.

6. Learn to lift and handle materials correctly.

7. Use machine guards when provided.

8. Take care on entering and leaving work area.

9. Develop a real determination to work safely.

Clothing and Foot Wear

a. Always wear an overall or apron.

b. All loose clothing must be tightened.

c. Shoes must be worn and should be strong to prevent damage to the feet by sharp pieces of materials on the workshop floor.

d. Do not wear plastic or rubber sandals as these invite serious accidents.

e. Proper gloves should be used for specific purposes.

f. Ear protectors should be used to protect eras from damage caused by loud noise.

g. Protective masks are used to protect the lungs from toxic and non toxic dusts.

Movement in the Workshop

Moving around the workshop is unavoidable. Do not run; walk when you have to move around.

Tools should be carried and stored in such a way that they do not become hazardous to other workshop users.

A tidy workshop is a safe workshop

The Workshop Floor

1. Do not obstruct the workshop gangways by stacking or storing materials along them.

2. Do not spill oil, paint or other materials on the workshop floor.

Fire and Accidents

1. Report any fire or accident to your teacher immediately.

2. You should find out where the various alarms in the workshop are located and how to use them.

Using Tools and Machines

1. Always use goggles and safety clothing when required. Below are various types of goggles or eye protectors which are useful in the workshop.

2. You should learn the appropriate and correct method of handling and using tools.

3. Before using a machine always find out where the start and stop switches are located.

4. You should never operate a machine unless you have been taught how to use it.

Safety signs and symbols

The aims of having these signs in the area is to remind the students and staff about health and safety and safe working practices in the practical environment.

The signs and symbols shown should be known to the student and examples should be seen in the practical workshop area.

Activity 9:

Try the 6 given questions below. Clearly write your name on your worksheet and send it on my Email-address for correction: ricardolentete@yahoo.com

1. State one example of the use of each of the following items of safety equipment:

a) Asbestos gloves

b) Clear goggles

c) Leather apron

d) Rubber gloves

e) Face shield

f) Barrier creams

g) Ear protectors

2. State the reason for having the following in the workshop:

a) Yellow lines on the floor

b) Non-slip flooring materials

3. State one reason for each of the following safety regulations:

a) Swarf must be removed from machines by means of a rake.

b) The exit door of a workshop must be kept free from obstruction.

c) Safety glasses must be used when drilling metals.

4. State one example of each of the following sources of danger in a workshop.

a) The presence of inflammable materials.

b) Working with or near equipment which has moving parts.

c) Work using substances which irritate the skin.

For each method mentioned above, state one method of minimising the danger.

5. List down ten safety precautions that should be observed in a workshop.

6. State the safety precautions to be observed when using the following tools:

a) Hammers

b) Bevel-edge chisels

c) Screwdrivers

d) Clamps

e) Scribers

f) Pliers

g) Coping saws

h) Files

i) Drills

j) Hacksaws

No comments:

Post a Comment